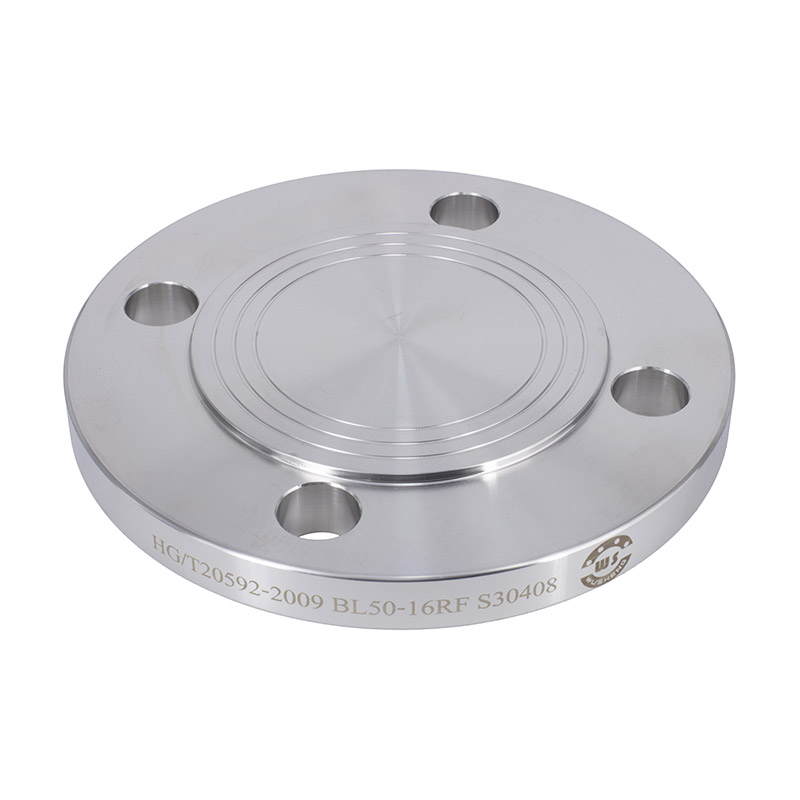

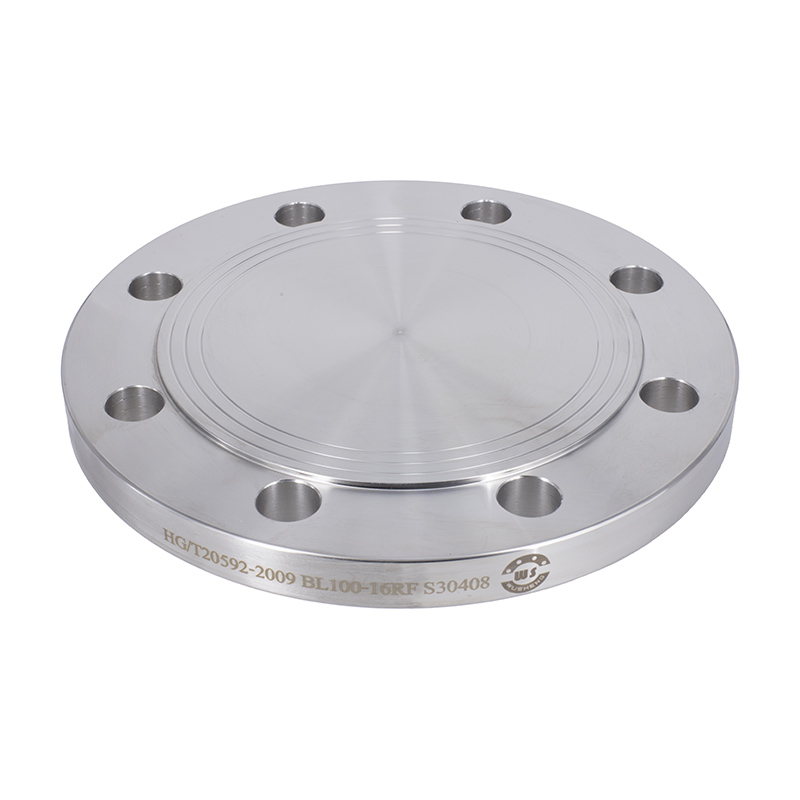

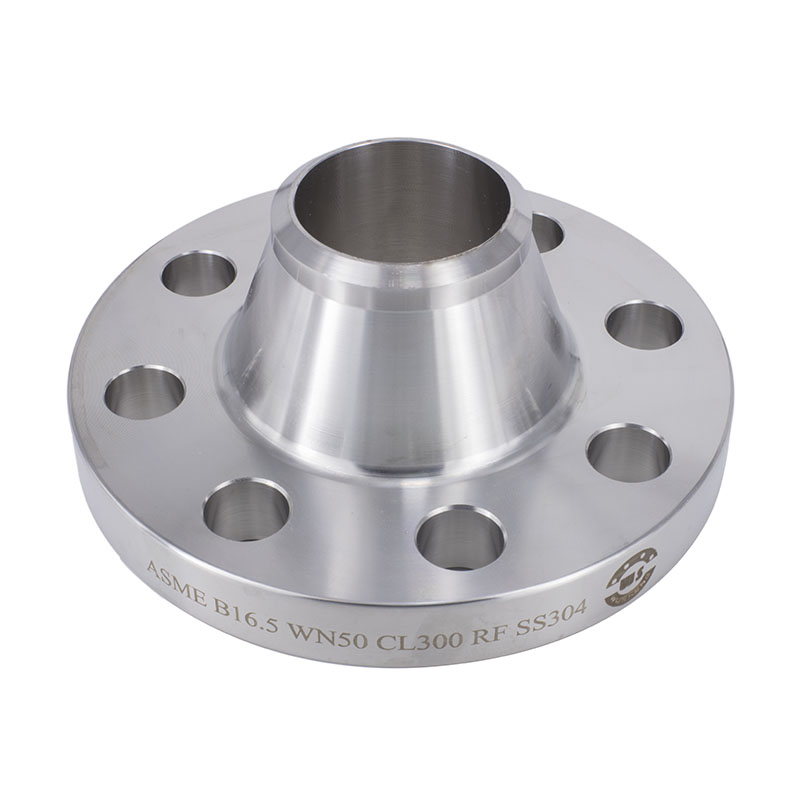

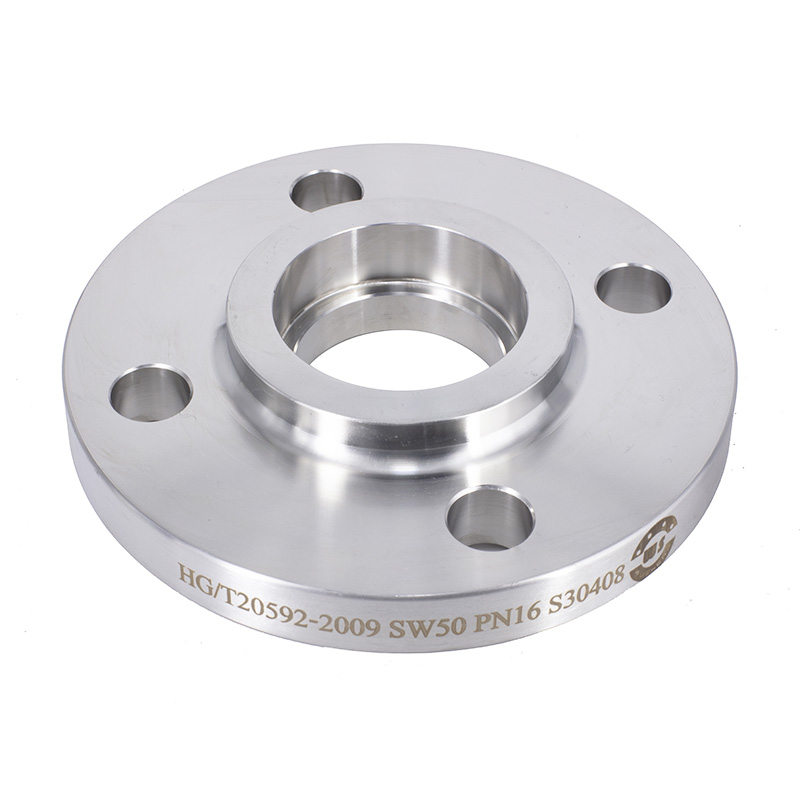

316 Stainless Steel Socket Weld Flanges

Wusheng 316 Stainless Steel Socket Weld Flanges are manufactured in China by Zhejiang Wusheng Pipe Industry Co., Ltd. using high-quality 316 stainless steel.Wusheng 316 Stainless Steel Socket Weld Flanges are a type of flange that are welded to the end of a pipe and provide a strong and leak-proof connection.

Send Inquiry

Zhejiang Wusheng Pipe Industry Co., Ltd. is a professional manufacturer of flanges such as 316 Stainless Steel Socket Weld Flanges and elbows. The company has international standard production workshop, perfect production equipment and testing center. Products cover high, medium and low pressure pipe fittings, flanges, piping and other pressure pipe components and deep processing product series.The company is market-oriented, quality as the center, talent as the driving force; Adhering to the business philosophy of "integrity, quality, maturity, win-win", with the purpose of standardization, modernization and internationalization, the goal is to become an international pipeline equipment supplier.

Wusheng 316 Stainless Steel Socket Weld Flanges Introduction

Wusheng 316 Stainless Steel Socket Weld Flanges Introduction

Wusheng 316 Stainless Steel Socket Weld Flanges Another function of the socket weld flange is the shoulder inside the socket. The shoulder allows the pipe to slide onto the flange until it touches the shoulder to ensure proper placement of the pipe on the flange. After the pipe has touched the shoulder, the welder can attach the flange to the pipe by butt welding around the socket. The tube is the same height as the shoulder in the socket and can provide the same strength as the internal weld of the sliding flange, but without the grinding associated with the internal weld.We can provide a 316 Stainless Steel Socket Weld Flanges price list when received the quotation Wusheng is a China S316 Stainless Steel Socket Weld Flanges suppliers.Due to the reasonable design of products, advanced technology, reliable performance and stable quality, by the majority of users rely on and praise.

Wusheng 316 Stainless Steel Socket Weld Flanges Parameter (Specification)

Wusheng 316 Stainless Steel Socket Weld Flanges Parameter (Specification)

|

FLANGE |

|

|

Technics |

Forged |

|

Size |

1/2"-80"(DN15-DN2000) |

|

Pressure |

150 lbs - 2500lbs |

|

Standard |

ANSI B16.5/ANSI B16.47/API 605 MSS SP44,AWWA C207-2007/ANSI B16.48 |

|

Material |

Stainless steel: ASTM A182 310/F316/316L/F316/F316L, F321, F347. |

|

Surface Treatment |

Polish |

|

Application Fields |

Chemical Industry /Petroleum Industry /Power Industry/Metallurgical Industry |

Wusheng 316 Stainless Steel Socket Weld Flanges operating principle

Wusheng 316 Stainless Steel Socket Weld Flanges operating principle

316 Stainless Steel Socket Weld Flanges is usually used for small tubes with diameters less than DN40 and is more economical. Butt welding is usually used for parts DN40 and above. Socket welding is the process of first inserting a socket and then welding it (for example, there are flanges called socket flanges, which are convex welded flanges, which are connected to other parts (such as valves). Butt welded flange and pipe welded form of connection, socket welding is usually inserted into the flange and welded, butt welding is the use of butt welded flange to weld the pipe to the butt surface. Although X-rays are not available, butt welding accepts butt welding, so it is recommended to use butt welding flanges to improve welding inspection requirements.

Butt welding is usually more demanding than socket welding and post welding. The quality is also good, but the detection means is more strict, butt welding needs X-ray inspection, socket welding can be used for magnetic particles or permeability test (carbon powder, penetrating carbon steel), such as stainless steel), if the fluid in the pipeline welding requirements are not high, it is recommended to use socket welding, convenient detection of the connection type is mainly small diameter valves and pipes, for pipe joints and pipe welding, Small diameter pipe is usually thin wall, prone to edge dislocation and ablation, and difficult to butt welding, suitable for socket welding and socket

316 Stainless Steel Socket Weld Flanges function

316 Stainless Steel Socket Weld Flanges function

316 Stainless Steel Socket Weld Flanges By eliminating the need for internal welding, socket welding flanges save assembly time while maintaining the same strong connection. By matching the inner hole of the socket to the inner diameter of the pipe, thicker sockets provide optimal flow and smooth transition in case of mismatches. Socket welding flanges can be made of mild steel and stainless steel and can be used in food grade and non-food grade piping. Flanges are also suitable for high and low pressure applications.

Welded socket is often used under high pressure because of its reinforcing effect, but socket welding also has shortcomings, one is that the stress condition after welding is not good, difficult to completely melt. The trend is: there is a gap in the pipeline system, so it is not suitable for gap corrosion sensitive media and high cleanliness requirements of the pipeline system; Use socket welding; There are also ultra-high pressure pipelines. Even in small diameter pipes, the wall thickness is large, and socket welding can be avoided as much as possible by butt welding.