Super Duplex F51 Steel Plate Flanges

Wusheng Super Duplex F51 Steel Plate Flanges are high-quality flanges used to connect pipes in various industries, known for their superior strength and resistance to corrosion. They are manufactured in China by Zhejiang Wusheng Pipe Industry Co., Ltd.

Send Inquiry

Zhejiang Wusheng Pipe Industry Co., Ltd. is a professional manufacturer of flanges such as Super Duplex F51 Steel Plate Flanges and elbows. Products are widely used in pump and valve, offshore platforms, ships, pressure vessels, petrochemical, boiler fluid, electric power, communications, high-speed rail, photovoltaic and other industries.

The epidemic has brought challenges to the metal pipe fitting industry both at home and abroad, as well as new development opportunities. Wusheng will base itself on the national market, closely combine the characteristics of the industry, dig deep into customer applications, solve users' pain points, rely on strong research and development strength, integrate cutting-edge technology concepts, and quickly respond to customers' changing needs. To provide industry customers with reliable, safe, high quality, easy to expand customized requirements and piping system engineering solutions.

Wusheng Super Duplex F51 Steel Plate Flanges Introduction

Wusheng Super Duplex F51 Steel Plate Flanges Introduction

Wusheng Super Duplex F51 Steel Plate Flanges refers to the PREN>40, containing 25%Cr and high molybdenum (>3.5%), high nitrogen (0.22% ~ 0.30%) of the two phase steel, The main brands are UNS S32550(UR52N+), S32750 (SAF 2507) and S32760(Zeron 100), developed by CLI of France, SANDVIK of Sweden and MATER+PLATT of Britain, respectively. Their deformation materials were introduced around 1990 and 1991, and have come onto the market in recent years.

The three steels are similar in composition, but differ in the amount of tungsten and copper.Since 2000, the development of modern duplex stainless steel has shown two trends. On the one hand, while paying attention to the thermal stability of steel structure, further improve the content of chromium, molybdenum and nitrogen in steel to obtain higher strength and better corrosion resistance, in order to adapt to the needs of modern industrial development and facilitate the competition with super austenitic stainless steel. Super duplex stainless steel with PRE values close to 50, such as SAF2707 HD and SAF 3207 HD.We can provide a Super Duplex F51 Steel Plate Flanges price list when received the quotation Wusheng is a China SSuper Duplex F51 Steel Plate Flanges suppliers.Due to the reasonable design of products, advanced technology, reliable performance and stable quality, by the majority of users rely on and praise.

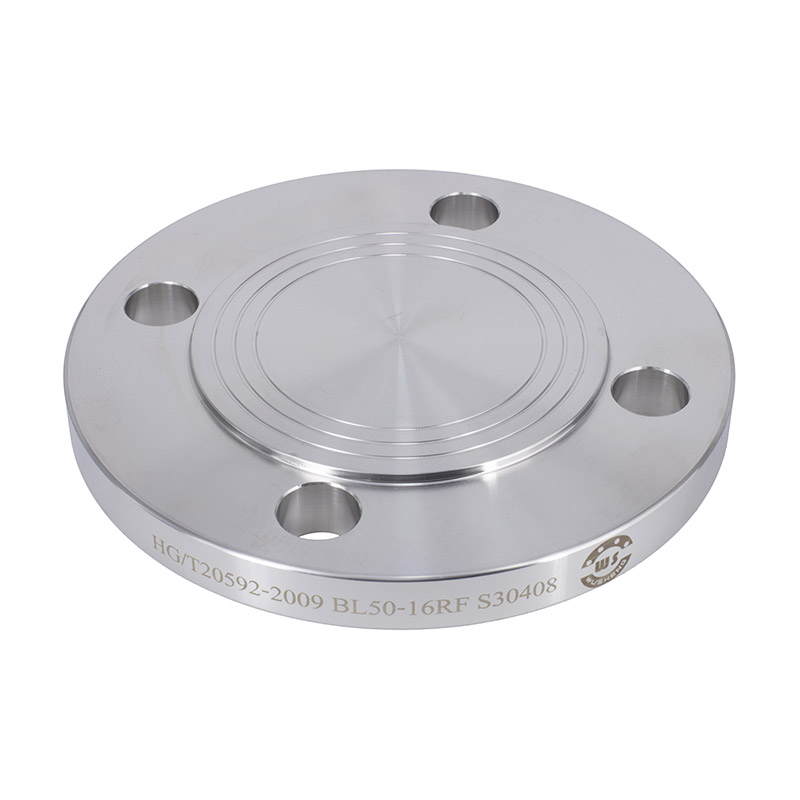

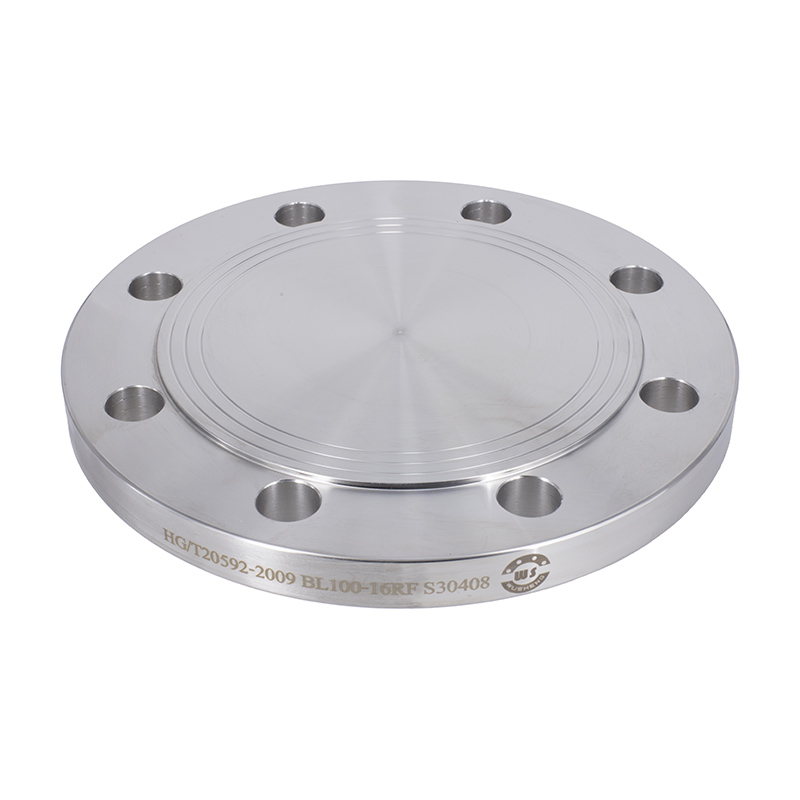

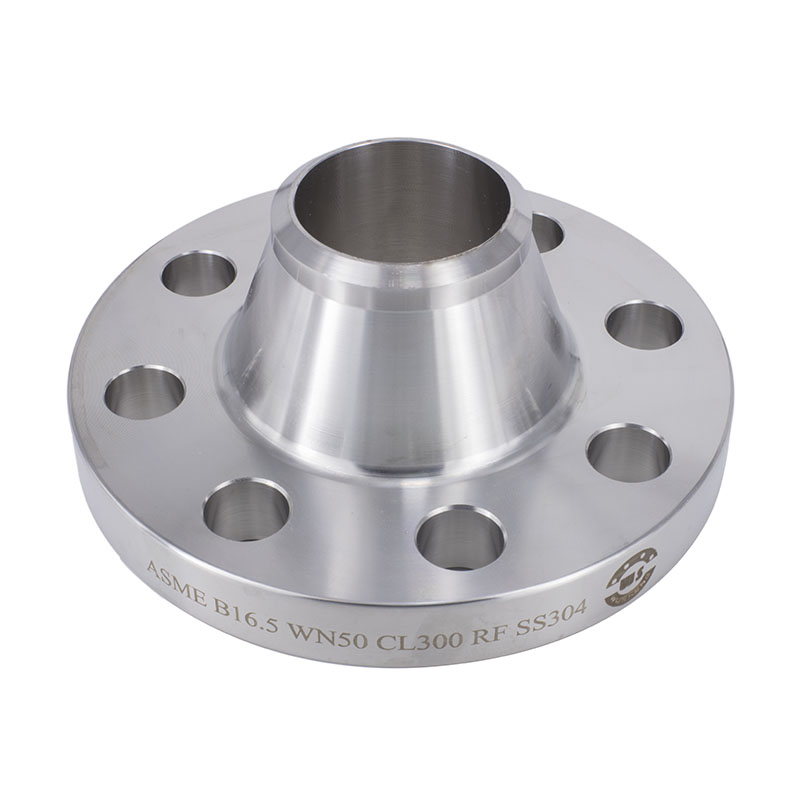

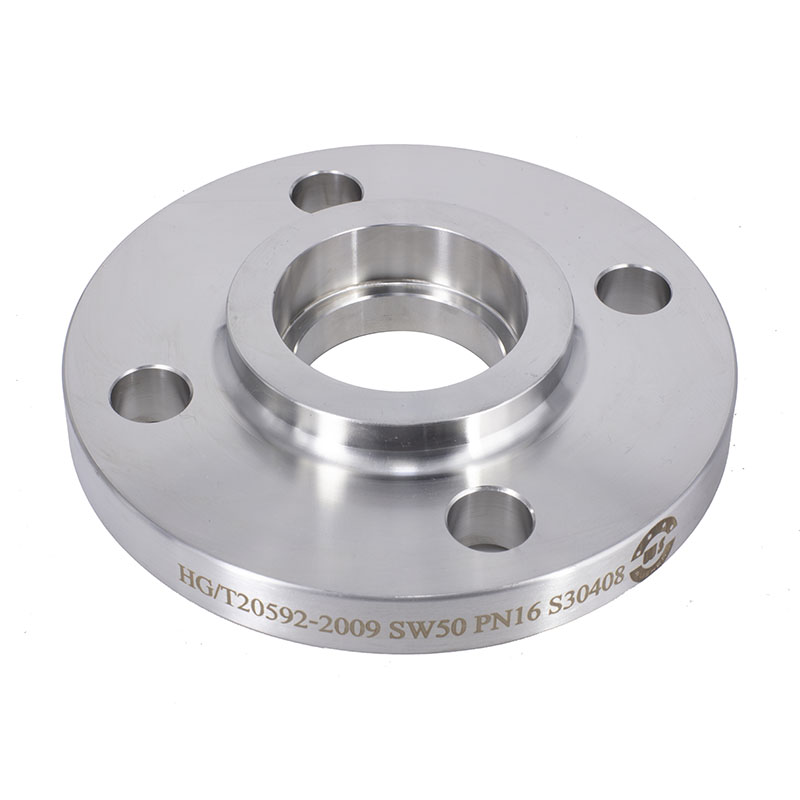

Wusheng Super Duplex F51 Steel Plate Flanges Parameter (Specification)

Wusheng Super Duplex F51 Steel Plate Flanges Parameter (Specification)

|

FLANGE |

|

|

Technics |

Forged |

|

Size |

1/2"-80"(DN15-DN2000) |

|

Pressure |

150 lbs - 2500lbs |

|

Standard |

ANSI B16.5/ANSI B16.47/API 605 MSS SP44,AWWA C207-2007/ANSI B16.48 |

|

Surface Treatment |

Polish |

|

Application Fields |

Chemical Industry /Petroleum Industry /Power Industry/Metallurgical Industry |

Wusheng Super Duplex F51 Steel Plate Flanges material Introduction

Wusheng Super Duplex F51 Steel Plate Flanges material Introduction

On the other hand, turn to the development of low nickel and no precious element molybdenum or containing only a small amount of molybdenum economic Super Duplex F51 Steel Plate Flanges , in order to reduce the production cost and price of duplex stainless steel, and improve the thermal workability and weldability of duplex stainless steel. Thus increasing the competitiveness of duplex stainless steel with other types of universal stainless steel, especially 304, 316 chromium-nickel austenitic stainless steel. There are already SAF 2304, AL 2003, LDX2101, Armo Nitronic 19D,ATI 2102, 2201, 2202, and LDX2404, which were introduced in 2000. The mass production and application of economic duplex stainless steel has brought great impact on the survival and development of the first generation of 18Cr type (containing about 3% molybdenum) duplex stainless steel 3RE60.

Super Duplex F51 Steel Plate Flanges physical metallurgy

Super Duplex F51 Steel Plate Flanges physical metallurgy

Super Duplex F51 Steel Plate Flanges In the development process of duplex and super duplex stainless steel, some problems of physical metallurgy have aroused people's attention. For example, the amount of Cr%+Mo% in steel should be greater than or equal to 21% in order to prevent martensitic transformation caused by cold working forming, which will lead to the deterioration of steel properties.

The effect of cold deformation on martensitic formation and corrosion resistance of the improved 18-5 duplex stainless steel (Cr+Mo content is 21%, N content is 0.07% and 0.10%) shows that the formation and increase of martensitic will reduce the stress corrosion resistance and pitting resistance of the steel.

For example, in order to increase the corrosion resistance of duplex stainless steel, in improving the amount of chromium and molybdenum in steel, to Cr%+Mo% is greater than or equal to 35% caused by the thermal stability of duplex stainless steel microstructure decline, equal precipitation between metals, resulting in plasticity, toughness, hot processing and welding and corrosion resistance of the deterioration of the necessary preventive measures.

For another example, nitrogen is a very useful and important element, but the addition of a large amount of nitrogen will cause the formation of chromium nitride and precipitation along the grain boundary, which will cause corrosion damage such as intergranular corrosion and toughness decline. The nitrogen content in steel exceeds the solid solution content of steel, resulting in a large number of waste products due to the escape of nitrogen during the solidification process of steel. If a large amount of manganese is added in order to improve the solid solubility of nitrogen in steel, the harm of forming manganese sulfide should also be evaluated.